Common abnormalities and treatment of injection molded produ

欄目:Industry News 發布時間:2021-06-03 15:19

Anomalous phenomenon, product, cause, solution Crack 1. The mold is too cold to adjust the mold temperature 2. Cooling time is too long, reducing cooling time 3. Plastic and metal inserts shrink differently. Metal inserts are preheated. 4....

Anomalous phenomenon, product, cause, solution

Crack 1. The mold is too cold to adjust the mold temperature

2. Cooling time is too long, reducing cooling time

3. Plastic and metal inserts shrink differently. Metal inserts are preheated.

4. The ejector device is unbalanced in inclination, and the ejector cross-sectional area is small or improperly distributed. Adjust the ejector device or reasonably arrange the number of ejector pins and their positions.

5. The production slope is not enough, the demoulding is difficult, and the draft angle is correctly designed.

There are ripples on the surface of the product. 1. The material temperature is low and the temperature is high.

2. Injection pressure The material temperature is high, which can reduce the injection pressure, and vice versa.

3. Low mold temperature Increase mold temperature or increase injection pressure

4. The injection speed is too slow. Increase the injection speed.

5. The gate is too small.

The brittleness of the product decreases. 1. The material temperature is too high, the plastic decomposes, the material temperature is lowered, and the residence time of the material in the barrel is controlled.

2. Excessive stress in plastics and inserts Preheat the inserts to ensure a certain thickness of plastic around the inserts

3. The number of times of plastic recycling is controlled.

4. Plastic water content, preheating and drying of raw materials

Difficulty in demoulding 1. Poor structure of the mold ejection device Improved ejection design

2. The mold cavity is not enough to correct the mold.

3. The cavity temperature is not suitable. The mold temperature is properly controlled.

4. The cavity has seams or materials. Clean the mold

5. The molding cycle is too short or too long. Properly control the injection cycle.

6. The core has no air inlet. Modify the mold.

Insufficient product size 1. Unstable machine circuit or oil system Corrected electrical or hydraulic system

2. The molding cycle is different. Control the molding cycle to make it consistent.

3. Temperature. time. Pressure change adjustment, control is basically the same

4. Plastic pellets vary in size. Use uniform plastic.

5. Uneven mixing ratio of recycled scrap and new material. Control mixing ratio to make uniform

6. Uneven feeding control or adjust the feeding evenly

Peeling and delamination of parts 1. Different plastics mixed with a single variety of plastic

2. Different grades of the same plastic are mixed with the same grade of plastic

3. Poor plasticization, increase molding temperature

4. Mix in foreign matter, clean up raw materials, and remove impurities.

Weld marks 1. The plastic temperature is too low. Increase the barrel. Nozzle and mold temperature

2. Too many gates Reduce the gate or change the gate location

3. Excessive release agent The atomization release agent is used. Reduce usage

4. The injection speed is too slow. Increase the injection speed.

5. The mold temperature is too low to increase the mold temperature

6. The injection pressure is too small to increase the injection pressure

7. Die exhaust is bad. Increase the mold vent hole.

Insufficient injection 1. Lower barrel and nozzle temperature Increase barrel and nozzle temperature

2. The mold temperature is low, and the mold temperature is raised.

3. Insufficient amount of feed, increase the amount of feed properly

4. The number of parts exceeds the maximum injection volume of the injection molding machine.

5. The runner and gate are too small. Increase the gate size appropriately.

6. The injection pressure is too low or the injection speed is too slow. Increase the injection pressure or increase the temperature, and increase the injection speed.

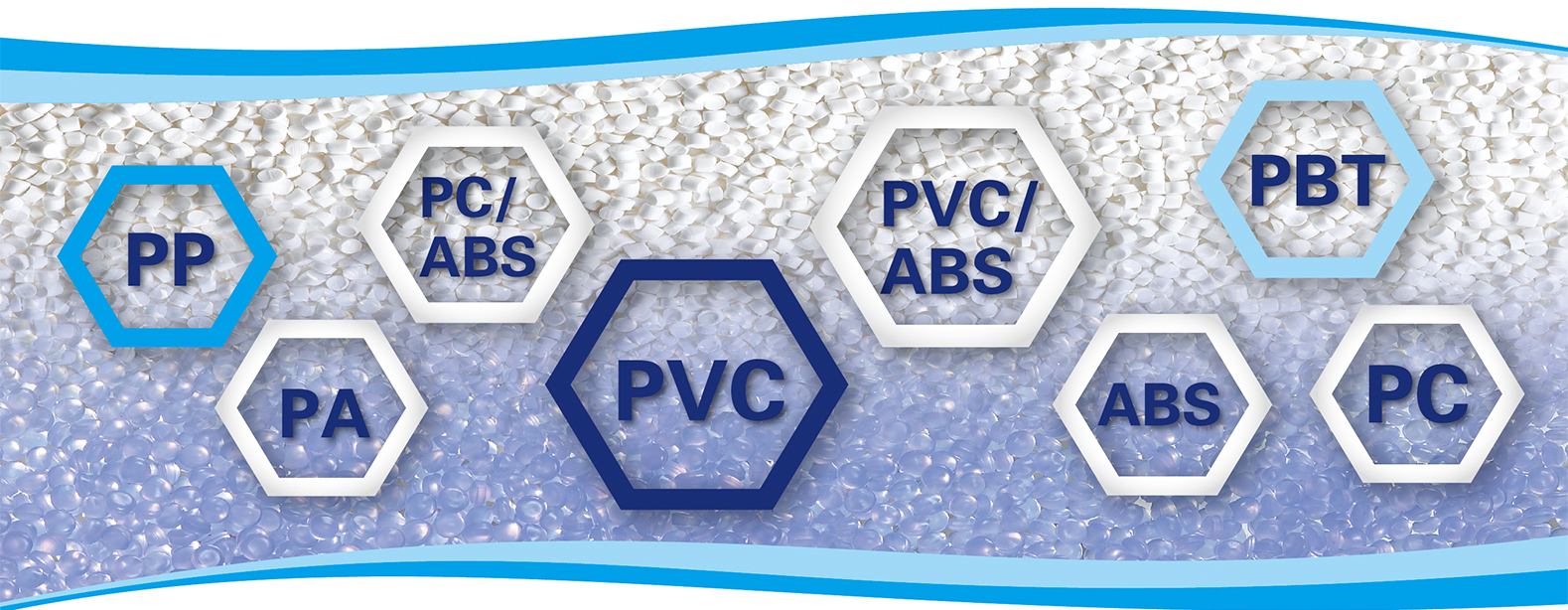

Wuxi Jiahong Plastic Technology Co., Ltd. has nearly 30 years of experience in research and development and granulation of modified PVC pellets. The professional technical service team can provide one-stop system solutions for customers. For more information about the product, please visit our official website: hnqtfy.cn, consult online customer service or call the hotline. Fixed line: 0510-68755207 Mobile: 15190220696, we will be happy to help you.

(Disclaimer: All the tutorials and resources included in this site are from the Internet, and the copyrights are owned by the original author and its website. Although this site strives to preserve the original copyright information, it may not be able to determine its origin due to various reasons. The true source, please forgive the original author! If you have any objection to the attribution of the tutorial and resources of this site, please notify Xiaobian immediately, the situation is true, we will delete it in the first time.)